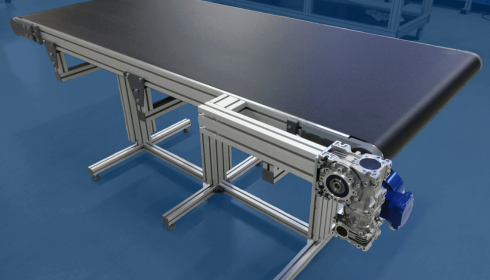

Industrial conveyor systems rarely stop moving. Whether carrying lightweight packages or heavy materials, the framework supporting those belts must endure ongoing vibration, shifting pressure, and long-term stress without losing alignment. MiniTec Aluminum Framing has become a reliable choice for handling this type of continuous operation because of its durability, rigidity, and adaptability across automation environments.

Minitec Framing Maintains Stable Support Under Steady Conveyor Movement

A well-designed conveyor support system depends on consistent structural stability. MiniTec extruded aluminum framing provides that foundation through its engineered profile design, which maintains even weight distribution and limits vibration during constant motion. The framing sections lock together tightly, forming a unified structure that resists small shifts over extended production hours.

This continuous support prevents the slow sagging or frame separation that often occurs in less rigid systems. With precise connector fittings and robust T-slot profiles, the framework remains balanced even when conveyor speed, torque, or load patterns vary. The result is a modular aluminum framing system that stays reliable through long operational cycles.

Its Modular Rails Distribute Ongoing Loads with Consistent Balance

The modular rails built into MiniTec aluminum framing material are engineered to handle dynamic loads by dispersing pressure evenly across the frame. This balance minimizes high-stress points that can lead to deflection or uneven belt tracking. Each aluminum profile interlocks to spread the conveyor’s weight throughout the structure, keeping belt surfaces smooth and stable.

In heavy-duty settings, this even load transfer helps prevent premature wear on bearings, rollers, and motors. The open-slot system of the MiniTec aluminum frame kit also allows easy integration of braces or additional supports when line extensions or new conveyor sections are added, without the need for welding or redesign.

Reinforced Connectors Keep Frame Alignment Firm During Long Run Cycles

Continuous conveyors demand more than just strong materials—they require precise alignment over long periods. MiniTec’s reinforced connectors lock profiles in place to maintain that alignment even under vibration or shifting payloads. These components form the backbone of the frame’s stability, ensuring joints don’t loosen or twist.

Unlike rigid steel structures that often need realignment, MiniTec’s connectors can absorb minor shifts without losing integrity. This advantage makes the modular system highly dependable in automated facilities where conveyors run through multiple shifts each day. The connectors’ precision-fit engineering also allows for quick reconfiguration if conveyor layouts change.

Aluminum Profiles Resist Flexing When Conveyors Operate Continuously

Flexing is one of the silent problems that can compromise conveyor accuracy. The MiniTec aluminum framing material addresses this by combining high-tensile strength with lightweight design, which maintains rigidity under load. Its dense profile walls and consistent extrusion tolerances minimize bending even in wide-span conveyors.

Over time, reduced flex means belts stay level, reducing friction and maintaining smoother motion. This structural consistency enhances the overall service life of conveyor belts and drive systems, which depend on stable framing to operate at peak efficiency day after day.

Structural Channels Manage Repeated Weight Transfer Without Distortion

Continuous conveyor use produces rhythmic pressure that tests the strength of framing channels. MiniTec’s structural channels manage that repeated force through reinforced geometries that resist distortion. The internal design of the profiles allows weight to pass through the frame rather than concentrating at connection points. This architecture keeps conveyors aligned and level through repetitive motion, making the system ideal for facilities where production rarely pauses. Even after months of nonstop cycles, the framing maintains its original dimensions, demonstrating why MiniTec extruded aluminum framing is preferred for automation lines requiring long-term stability.

Profile Rigidity Supports Uninterrupted Belt Motion and Payload Flow

In conveyor operation, even the slightest frame movement can disrupt belt tracking or product flow. The rigidity of MiniTec profiles ensures uninterrupted motion by maintaining parallel alignment across support rails. Each section of the frame works together to resist torque from drive motors and tension from conveyor belts.

This mechanical balance keeps payloads moving efficiently, whether light electronics or dense materials. With precision extrusion and customizable assembly, the aluminum frame kit enables operators to fine-tune rigidity for their exact application—supporting continuous use without overbuilding or excess weight.

Cross-bracing Options Strengthen Load Endurance over Extended Use

Cross-bracing is one of the most effective ways to reinforce endurance in a modular aluminum framing system. MiniTec’s framework offers several configurations that enhance stiffness across long conveyor spans. The cross-braces connect profiles diagonally, dispersing both vertical and lateral loads to reduce movement during operation.

Facilities that incorporate cross-braced designs report fewer adjustment needs over time. These reinforcements extend the life of both framing and conveyor components by maintaining alignment through heavy use. The adaptability of the MiniTec aluminum frame kit also allows additional bracing to be installed later as production demands grow.

System Components Sustain Conveyor Force Without Compromising Stability

Continuous conveyor operation applies constant force across all system components. MiniTec’s profiles, fasteners, and connectors are engineered to handle this without compromising stability or precision. The structural combination keeps vibration low, which helps motors and sensors operate with less strain. This endurance translates directly into lower maintenance needs and greater uptime. Factories that depend on long conveyor runs find that the MiniTec aluminum framing material offers the resilience of steel systems with the flexibility and ease of reconfiguration only aluminum can provide. Minitec Solutions supplies these framing systems and accessories, helping facilities design conveyor structures that maintain strength and accuracy through constant use.